Our company

CHT Srl: Experience, future and passion

Our story

Yesterday

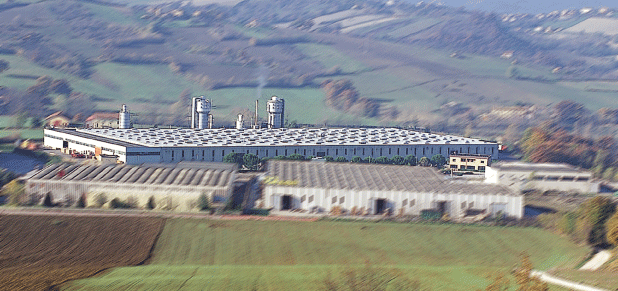

The company was founded in the 50's as a producer of components for both kitchens and furniture in general. During the 70's the company have started the development of the laminate hot-bending technology, also known as “postforming” technology. At the end of the 80's, the company is the biggest Italian producer of components for the furniture industry, which was booming at the time. Unfortunately, during the next 10 years, the real estate field experienced a strong crisis, which affected also the furniture producers. In December 1999, the former shareholders of the company decided to dismiss it and sold it to the actual owners.

Today

Since beginning of the year 2000, the company has undertaken a deep modification, made through important investments, made during the years, and still ongoing. In the last decade, CHT has changed from being a producer of many different components for the furniture industry, mainly in chipboard, to a specialized manufacturer of mainly horizontal elements, such as worktops, tabletops and shelves, made with chipboard, multiply wood, and since 2023, also with the eco-panel Greengridz®, and veneered with HPL or CPL laminates, Fenix or similar, etc.. Thanks to its technology and process layout, CHT is able to supply all the products both with industrial specifications, as well as in Just in time mode.

Products

Specifications and technical feature

Technical features of CHT chipboard

All the chipboard used by CHT, is produced by leading European companies, environmentally-friendly and officially certified, and all operating according the current regulations.

The chipboard purchased is made both with fresh poplar as well as with recycled wood.

Technical features:

| Technical features (panel V70 30 mm thick) | |

|---|---|

| 1) Janka Hardness | 300 Kgf/cm2 |

| 2) Screw Holding | 50 N/mm |

| 3) Swelling | ≤ 12% |

| 4) Density | 650 Kg/m3 |

| 5) Bending strength (M O E) | 1700 N/mm2 |

| 6) Bending strength (M O R) | 11 N/mm2 |

| 7) Impact resistance with 500g steel ball from 1 meter height | 20mm |

| 8) Composition % wood materia - % glueingmaterials | 70% - 30% |

Technical features of CHT Multiply

All the Multiply used by CHT comes from leading companies in the European community, all with official environmental certifications, and in full compliance with current laws.

The multiply purchased is all made with fresh poplar and it is jointed in CHT, in the sizes and dimensions ordered by the customers.

Technical features:

| Technical features (31.2 mm thick panel) | |

|---|---|

| 1) Janka Hardness | 450 Kgf/cm2 |

| 2) Screw Holding/td> | 79 N/mm |

| 3) Swelling | ≤ 6% |

| 4) Density | 450 Kg/m3 |

| 5) Bending strength (M O E) | 7800 N/mm2 |

| 6) Bending strength (M O R) | 57 N/mm2 |

| 7) Impact resistance with 500g steel ball from 1 meter height | 13mm |

| 8) Composition % wood matter - % glueingmaterials | 93% - 7% |

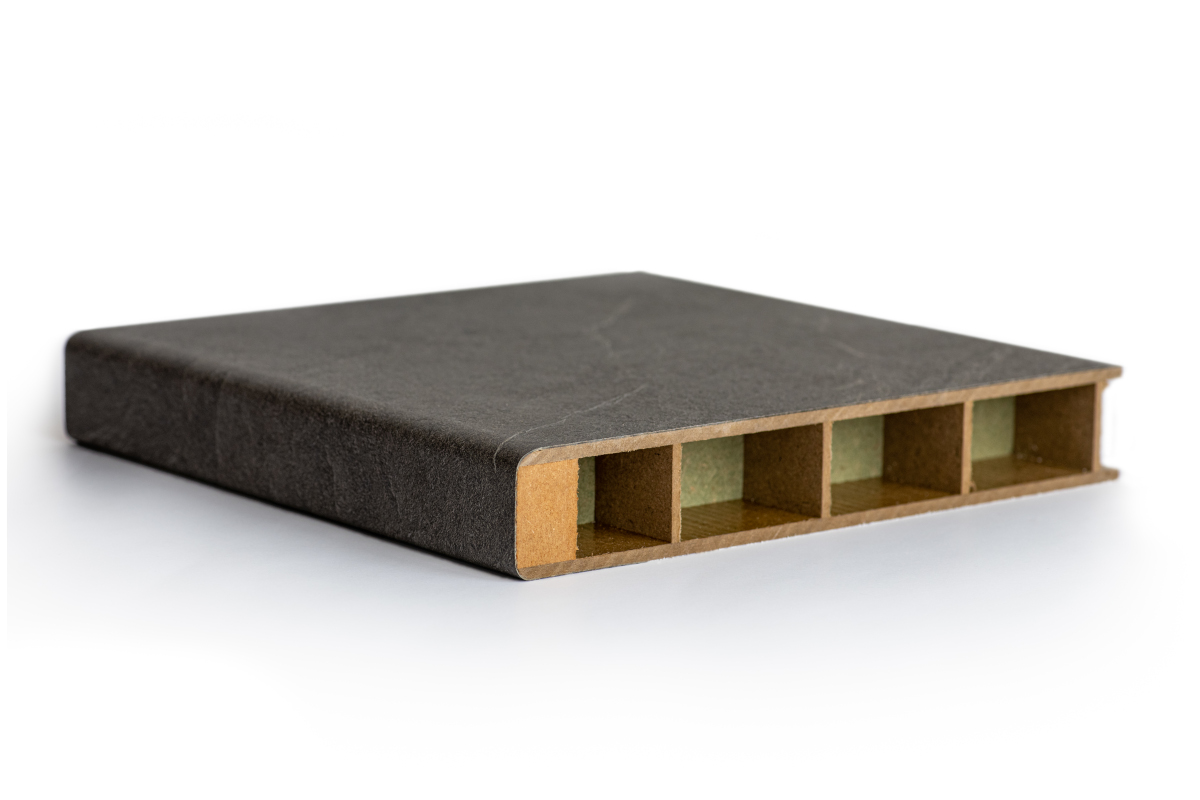

Technical features of the CHT Greengridz®

Greengridz® represents the future of base panels. Made only with specifically harvested wood in certified forests, is absolutely a great innovation. Being 60% lighter than chipboard and 40% than multiply wood, it allows to reduce sensibly the emissions related to logistic and the disposal of the product.

Greengridz® is totally recyclable end eco-friendly and it is suitable for all uses where weight plays an important role (Shipbuilding, Caravan, Trains, etc..).

Technical features:

| Technical features (38 mm thick panel) | |

|---|---|

| 1) Density | 260 Kg/m3 |

| 2) Internal bonding | 0,7 N/mm2 |

| 3) Bending strength | 7 N/mm2 |

| 4) Modulus of elasticity | 900 N/mm2 |

| 5) Surface tension | 0,8 N/mm2 |

| 6) Moisture | 7+/-3 %% |

| 7) Surface absorption | >150 mm |

| 8) Formaldehyde content | CARB 2 mg/100 gr |

| 9) Swelling 24 H | 3% |

Project

Cht, thanks to the big production capacity as well as to its high level of flexibility, is able to produce specific orders, for the “projects” market, the HORECA customers, public offices or bids, or private ones, always made with the same high features and quality

Environment

Since 20 years, CHT invests continuously on environment and ecology, with a steady renovation of the machinery and production lines, allowing a progressive reduction of the CO2 emissions. Also suppliers are selected, not only in terms of quality of the product supplied, but also according to the production process used as well as the origin of the raw materials.

Circular Economy

The future goal for CHT is to create a total circularity of its products, ensuring both sustainability in the production phase, through the use of materials of certified origin, with longer life of use, lower weight and consequent increase in transportable volumes with the same CO2 emissions.

At the end of its life cycle, every product sold during the years, will be recycled or disposed, in the more eco-friendly and convenient way.

Moreover, always aiming to improve the future environment, CHT cooperates with companies which are promoting CO2 reduction, by using renewable energy resources, low-polluting production processes, transportation made with “green” means, etc..

Contact

How to contact CHT Srl

Address

Loc. Pian Del Cerro, 60043 Cerreto D'Esi (AN)

Phone:

+39 0732 67671

Pec:

chtsrl@pec.it

E-mail:

info@chtsrl.eu